Gyratory Sieve G2036-5

- Customization: Available

- Customized logo: Min. order 1 units

Introduction:

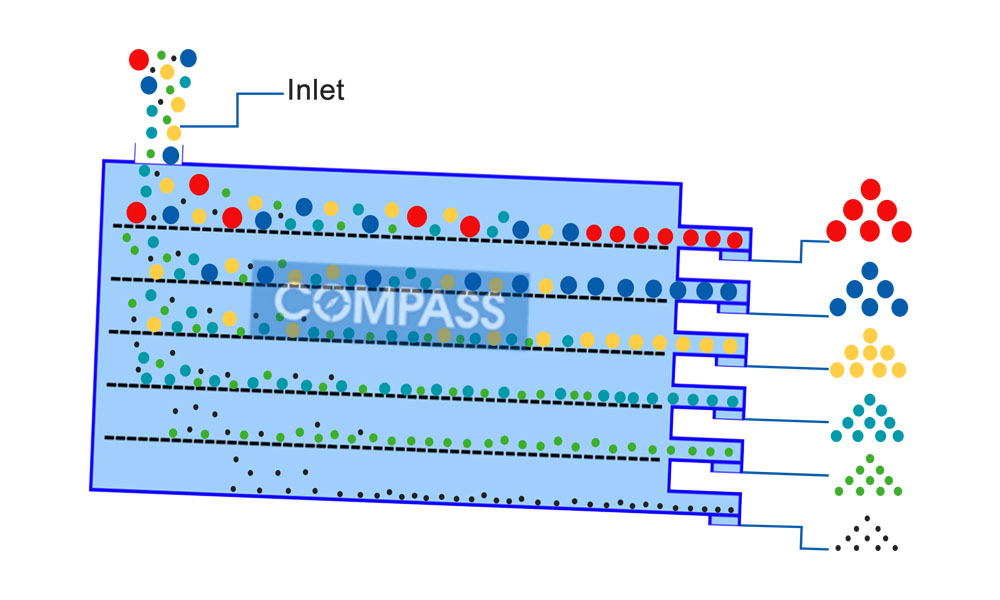

G2036-5 industrial sieving machine is a high capacity and high efficiency screening equipment, which is used to separate, filter and classify powder, granules and sliced materials according to different size.

Gyratory screening equipment uses the regular rotational motion and thin-layer screening design. The product moves along the elliptical trajectory from one end of the screen to the other end, and the product movement stroke is 20~50mm. Small particles pass the mesh and enter the next layer, finally products of different particle sizes are separated.

Features:

- One ~ five decks.

- Mesh size 0.1mm ~5mm.

- Bouncing ball cleaning.

- Efficiency up to 99.9%.

- Input capacity max. 15 tons per hour.

- Maintenance-free motors and bearings.

- Platform design and manufacturing.

Technical Data

| Material: | Q235 carbon steel + Alloy material |

| Color: | Powder coating, white + blue |

| Screen layer: | 5 |

| Outelet: | 6 |

| Screen dimension: | 2000*3600mm, 6.56 * 11.8 feet. |

| Mesh: | SS304 Stainless steel wire mesh |

| Mesh size: | 3~200 mesh, 0.075~6mm |

| Voltage: | 380~690v, 50/60hz, three phase |

| Bearing: | SKF |

| Motor NO.: | ABB, M2BAX-132MA |

| Power: | 7.5Kw, 1450r/min |

| Rotate speed: | 260Rpm |

| Max Inlet: | 12 tons per hour |

Download

User benefit:

Higher Final Passed Yield, Reduce Your Product Costs.

It refers to regular sampling testing of products after screening to test whether the particle size of the product is qualified.

There are three tests for yield rate:

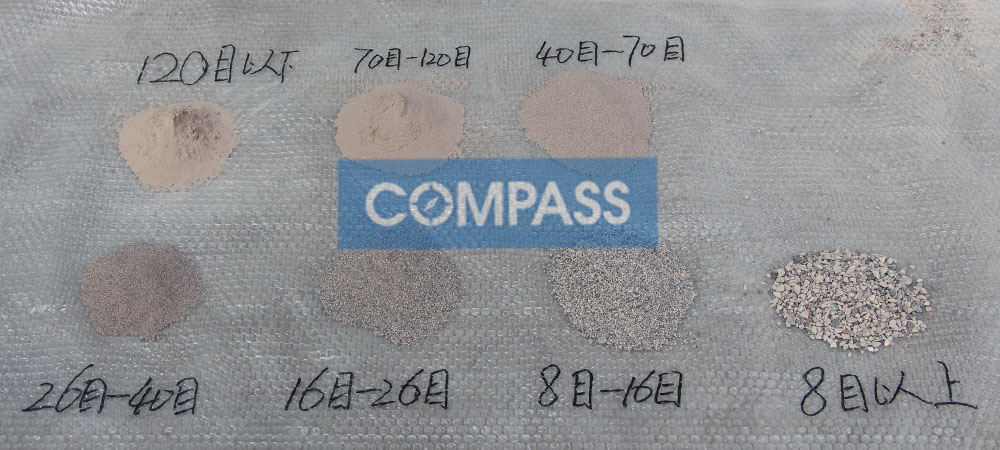

1. the product Purity.

For example, after screening treatment, mineral powder smaller than 70 mesh is screened twice, and 99.9% of the products pass the test, then the purity of the product is 99.9%. Products with purer particle size mean higher quality and competitiveness.

2. Good product Waste rate.

If among 200 tons of raw materials, 100 tons of products smaller than 100 mesh are obtained, and after screening by vibrating screen, you obtain 80 tons of products smaller than 100 mesh, then your development rate is 80%. Higher development rates mean less waste of good products and more output.

You can also visit the yield testing video to learn how to detect yield.

Change the screen easier, shorter maintain time.

According to the user’s feedback, it takes an average of 0.5 hours for the user to replace all the screens with new ones, only for the G2036-5 model vibrating screen. Only 2 operators and 3 sets of wrenches are required. At the same time, traditional mechanical design requires at least 2 hours, or even a whole day to let you change the screen.

This unique design will greatly reduce equipment maintenance costs and downtime, increase output and save money for users.

You can visit the guide video.

7*24 hours heavy duty running, less down time.

After more than 10 years of practice and continuous improvements, the G2036-5 sifting machine has the stable performance. You can use it 24/7. The very low failure rate ensures that your factory production line will not stop production because of the screen machine. You will get qualified separating quality from morning to night.

Service:

- Reply in time.

- Short lead time.

- Sample test.

- Machine assembly video and manual.

- One year warranty.

- Standard wearing parts after sales.