Comprendre les différents types de sable de fracturation et leurs utilisations dans la production pétrolière et gazière

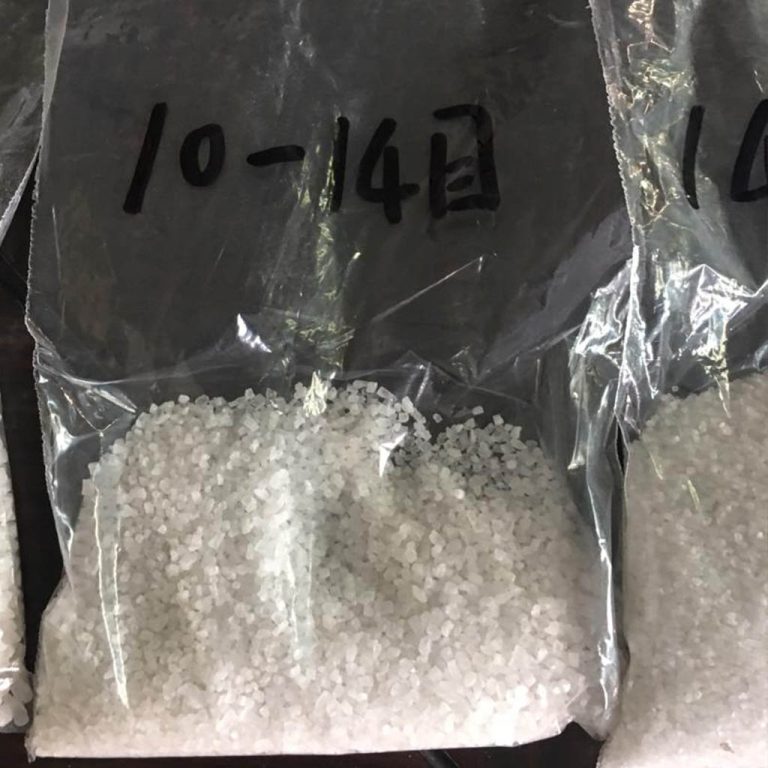

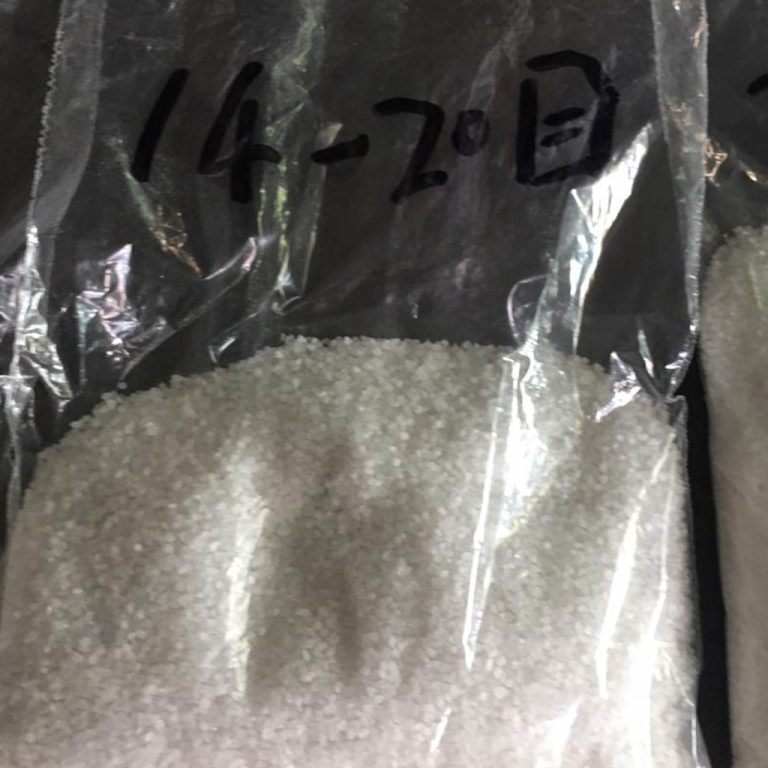

Le sable de fracturation, également connu sous le nom de sable de fracturation, est un composant essentiel de la production pétrolière et gazière. Il est utilisé pour maintenir les fractures créées dans les formations rocheuses lors du processus de fracturation hydraulique. Sans cela, les fractures se refermeraient et le pétrole et le gaz ne pourraient pas s’écouler.

N° de modèle

| Humide | Taille des mailles | Capacité Tonnes/Heure | G2036-3 | Sable de silice, sable de quartz, sable de fracturation |

| Sec | 2G2036-3 | Sable de silice, sable de quartz, sable de fracturation | 40 / 70 / 140 | 6 |

| Sec | 4G2036-2 | Sable de silice, sable de quartz, sable de fracturation | 40 / 70 / 140 | 10 |

| Sec | Silica sand, quartz sand, frac sand | Dry | 70 / 140 | 15 |

Finally, there is bauxite proppant, which is made from a combination of bauxite ore and other minerals. Bauxite proppant is used in high-temperature applications, such as geothermal wells, where it can withstand temperatures up to 600 degrees Fahrenheit.

Each type of frac sand has its own unique properties and uses, and it is important to understand the differences between them in order to ensure that the right type of sand is used for the job. By understanding the different types of frac sand and their uses, oil and gas producers can ensure that they are using the most effective and efficient type of sand for their operations.