Table of Contents

How Silica Sand Gyratory Screener Technology is Revolutionizing the Mining Industry

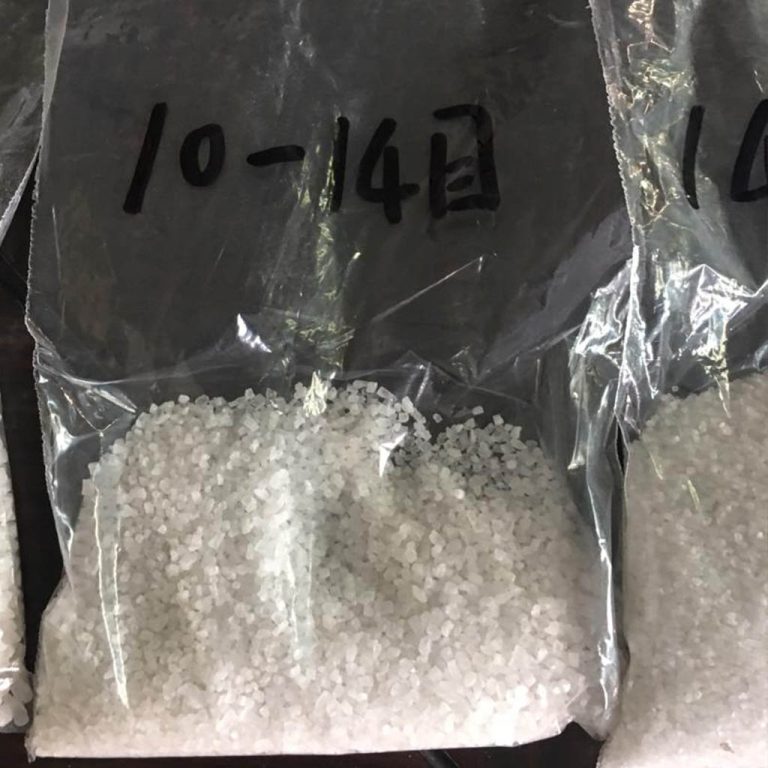

The mining industry is undergoing a revolution with the introduction of silica sand gyratory screener technology. This technology is revolutionizing the way that mining operations are conducted, making them more efficient and cost-effective. Silica sand gyratory screener technology is a game-changer for the mining industry. It allows for the efficient and accurate sorting of silica sand particles, which is essential for the production of high-quality products. The technology works by using a vibrating screen to separate the particles according to size. This process is much faster and more accurate than traditional methods, which can be time-consuming and costly.

Silica sand gyratory screener technology is a game-changer for the mining industry. It allows for the efficient and accurate sorting of silica sand particles, which is essential for the production of high-quality products. The technology works by using a vibrating screen to separate the particles according to size. This process is much faster and more accurate than traditional methods, which can be time-consuming and costly.

The Benefits of Utilizing a Silica Sand Gyratory Screener for Industrial Applications

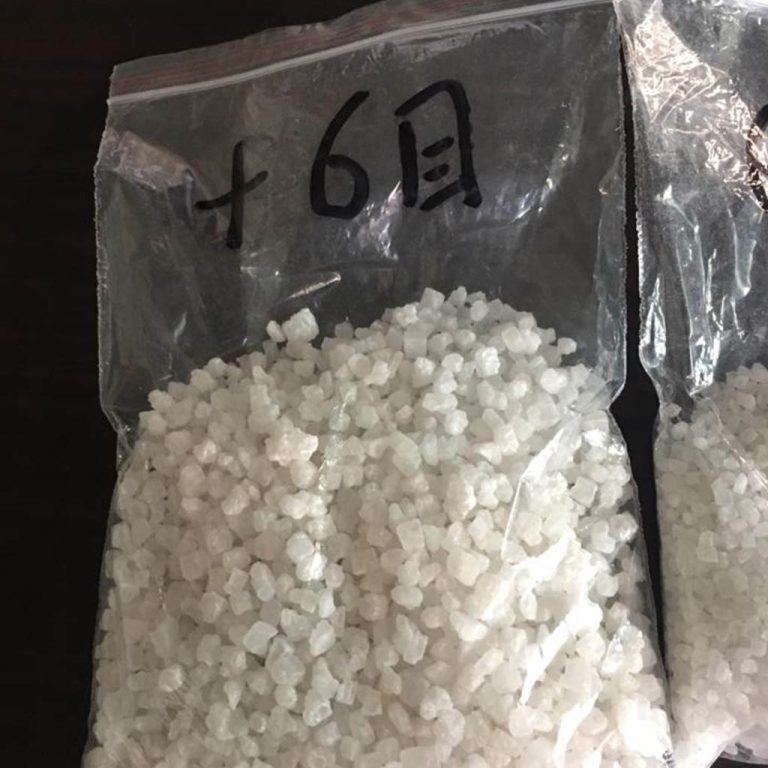

Are you looking for a reliable and efficient way to screen silica sand for industrial applications? If so, then a silica sand gyratory screener is the perfect solution for you! This type of screener is designed to quickly and accurately separate particles of different sizes, making it an ideal choice for a variety of industrial applications. Here are just a few of the benefits of using a silica sand gyratory screener: 1. Increased Efficiency: A silica sand gyratory screener is designed to quickly and accurately separate particles of different sizes. This means that you can get the job done faster and more efficiently, saving you time and money. 2. Improved Quality: By using a silica sand gyratory screener, you can ensure that the particles you are separating are of the highest quality. This will help you to produce a better end product and ensure that your customers are satisfied with the results.| Mesh size mm | Mesh numbe/ in2 | Wire Dia mm | Open Area % |

| 2 | 10 | 0.5 | 64 |

| 0.85 | 20 | 0.315 | 53 |

| 0.6 | 30 | 0.25 | 50 |

| 0.425 | 40 | 0.16 | 53 |

| 0.3 | 50 | 0.14 | 46 |

| 0.25 | 60 | 0.125 | 44 |