Table of Contents

How Frac Sand Vibro Screener Technology is Revolutionizing the Oil and Gas Industry

The oil and gas industry is undergoing a revolution with the introduction of frac sand vibro screener technology. This technology is revolutionizing the way oil and gas companies are able to process and transport frac sand, a key component in the hydraulic fracturing process.The Benefits of Utilizing a Frac Sand Vibro Screener for Improved Efficiency and Productivity

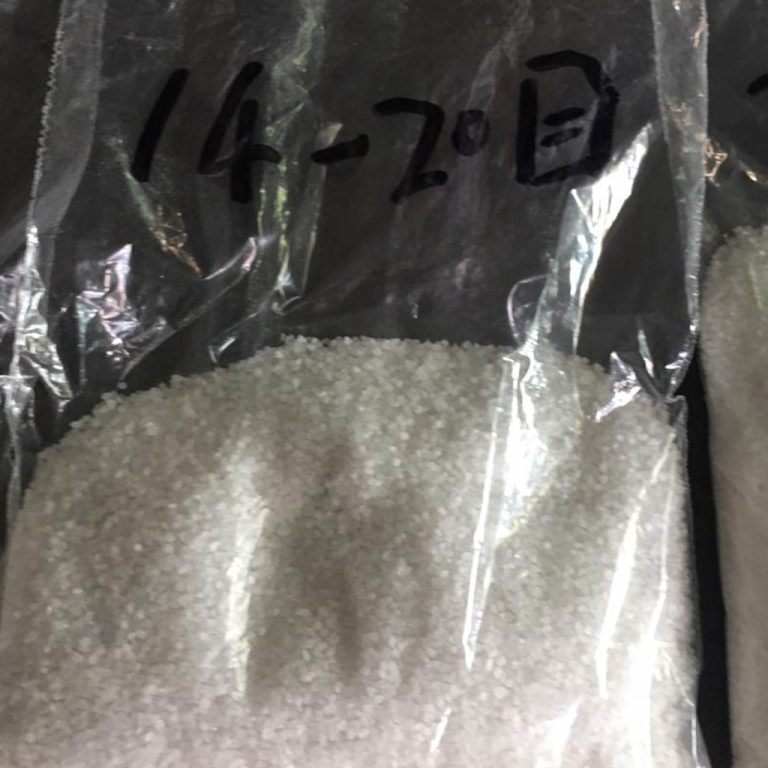

Utilizing a frac sand vibro screener can provide numerous benefits to any operation. This type of equipment is designed to efficiently and effectively separate particles of different sizes, allowing for improved efficiency and productivity. By using a vibro screener, operations can reduce the amount of time and labor needed to process frac sand, as well as reduce the amount of waste generated. The use of a vibro screener can also help to improve the quality of the frac sand being processed. By separating particles of different sizes, the screener can help to ensure that only the highest quality sand is used in the operation. This can help to reduce the amount of time and money spent on reworking or replacing sand that does not meet the desired specifications.

In addition, the use of a vibro screener can help to reduce the amount of dust generated during the processing of frac sand. By separating particles of different sizes, the screener can help to reduce the amount of dust that is created during the process. This can help to improve the safety of the work environment, as well as reduce the amount of time and money spent on cleaning up dust.

Overall, the use of a frac sand vibro screener can provide numerous benefits to any operation. By reducing the amount of time and labor needed to process frac sand, as well as improving the quality of the sand being used, operations can improve their efficiency and productivity. In addition, the use of a vibro screener can help to reduce the amount of dust generated during the process, improving the safety of the work environment.

The use of a vibro screener can also help to improve the quality of the frac sand being processed. By separating particles of different sizes, the screener can help to ensure that only the highest quality sand is used in the operation. This can help to reduce the amount of time and money spent on reworking or replacing sand that does not meet the desired specifications.

In addition, the use of a vibro screener can help to reduce the amount of dust generated during the processing of frac sand. By separating particles of different sizes, the screener can help to reduce the amount of dust that is created during the process. This can help to improve the safety of the work environment, as well as reduce the amount of time and money spent on cleaning up dust.

Overall, the use of a frac sand vibro screener can provide numerous benefits to any operation. By reducing the amount of time and labor needed to process frac sand, as well as improving the quality of the sand being used, operations can improve their efficiency and productivity. In addition, the use of a vibro screener can help to reduce the amount of dust generated during the process, improving the safety of the work environment.

| Model NO. | Deck | Weight Kg |

| G2036-1 | 1 | 5000 |

| G2036-2 | 2 | 5300 |

| G2036-3 | 3 | 5600 |

| G2036-4 | 4 | 5900 |

| G2036-5 | 5 | 6200 |