Table of Contents

Exploring the Benefits of Silica Sand Gyratory Screening for Industrial Applications

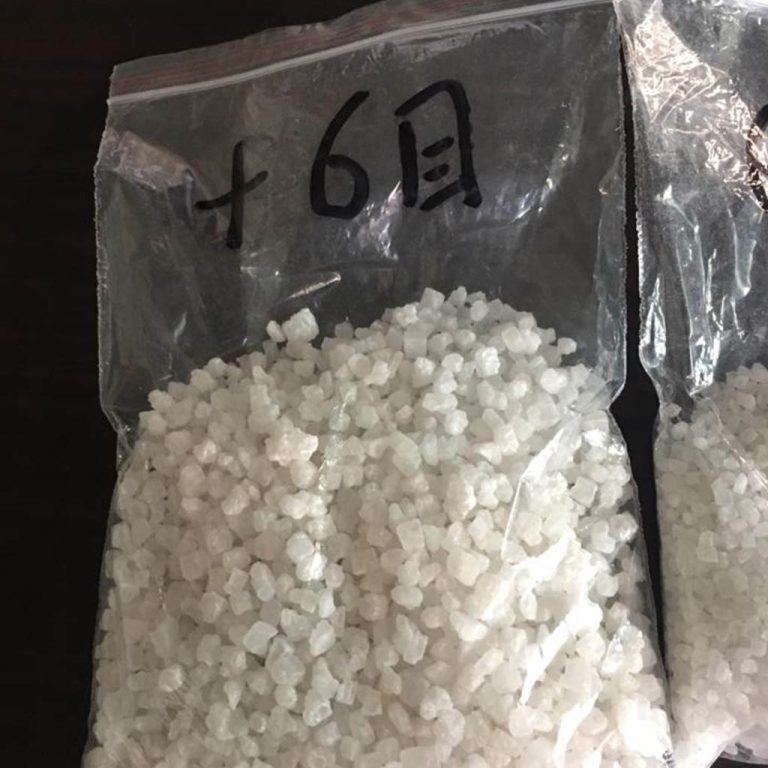

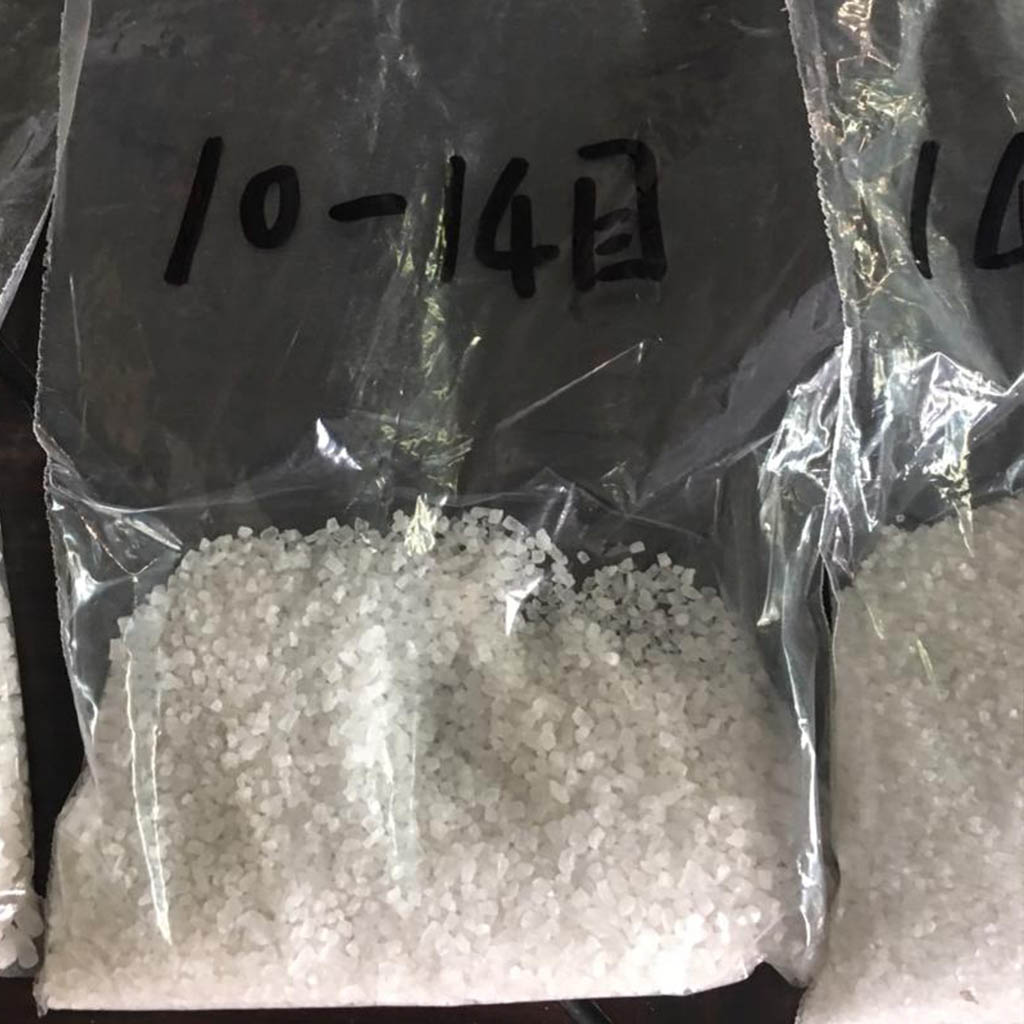

Are you looking for a reliable and efficient way to screen industrial materials? If so, you may want to consider using a silica sand gyratory screening system. This type of system is designed to separate particles of different sizes and shapes, making it ideal for a variety of industrial applications. Silica sand gyratory screening systems are highly efficient and can be used to screen a wide range of materials, including sand, gravel, crushed stone, and more. The system works by using a vibrating screen to separate particles of different sizes and shapes. The particles are then sorted into different categories based on their size and shape. The benefits of using a silica sand gyratory screening system are numerous. For starters, the system is incredibly efficient. It can quickly and accurately separate particles of different sizes and shapes, allowing you to quickly and accurately sort materials. Additionally, the system is incredibly durable and can withstand the rigors of industrial applications. Another benefit of using a silica sand gyratory screening system is that it is incredibly cost-effective. The system is relatively inexpensive to purchase and maintain, making it an ideal choice for businesses on a budget. Additionally, the system is incredibly easy to use and requires minimal training to operate. Finally, silica sand gyratory screening systems are incredibly safe. The system is designed to be used in a variety of industrial settings, and it is designed to be safe for both workers and the environment. Overall, silica sand gyratory screening systems are an excellent choice for a variety of industrial applications. The system is incredibly efficient, cost-effective, and safe, making it an ideal choice for businesses looking for a reliable and efficient way to screen industrial materials.Understanding the Mechanics of Silica Sand Gyratory Screening for Maximum Efficiency

Are you looking to maximize the efficiency of your silica sand gyratory screening process? If so, you’ve come to the right place! In this article, we’ll explain the mechanics of silica sand gyratory screening so you can understand how it works and how to get the most out of it. Gyratory screening is a type of screening process that uses a circular motion to separate particles of different sizes. It works by using a vibrating screen to move the particles in a circular motion, allowing them to separate based on size. The larger particles will move to the outside of the circle, while the smaller particles will move to the inside.

The key to maximizing the efficiency of your gyratory screening process is to ensure that the particles are evenly distributed across the screen. This can be done by adjusting the speed of the vibrating screen, as well as the angle of the screen. The angle of the screen should be adjusted so that the particles are evenly distributed across the entire surface.

Once the particles are evenly distributed, the next step is to adjust the speed of the vibrating screen. This will determine how quickly the particles move through the screen. If the speed is too slow, the particles will not be able to separate properly. If the speed is too fast, the particles will move too quickly and may not be able to separate properly.

Finally, it’s important to ensure that the particles are not too large or too small for the screen. If the particles are too large, they may not be able to move through the screen properly. If the particles are too small, they may not be able to separate properly.

Gyratory screening is a type of screening process that uses a circular motion to separate particles of different sizes. It works by using a vibrating screen to move the particles in a circular motion, allowing them to separate based on size. The larger particles will move to the outside of the circle, while the smaller particles will move to the inside.

The key to maximizing the efficiency of your gyratory screening process is to ensure that the particles are evenly distributed across the screen. This can be done by adjusting the speed of the vibrating screen, as well as the angle of the screen. The angle of the screen should be adjusted so that the particles are evenly distributed across the entire surface.

Once the particles are evenly distributed, the next step is to adjust the speed of the vibrating screen. This will determine how quickly the particles move through the screen. If the speed is too slow, the particles will not be able to separate properly. If the speed is too fast, the particles will move too quickly and may not be able to separate properly.

Finally, it’s important to ensure that the particles are not too large or too small for the screen. If the particles are too large, they may not be able to move through the screen properly. If the particles are too small, they may not be able to separate properly.

| Model NO. | Material | Moist | Mesh size | Capacity Tons /Hour |

| G2036-3 | Silica sand, quartz sand, frac sand | Dry | 40 / 70 / 140 | 6 |

| 2G2036-3 | Silica sand, quartz sand, frac sand | Dry | 40 / 70 / 140 | 10 |

| 4G2036-2 | Silica sand, quartz sand, frac sand | Dry | 70 / 140 | 15 |