Linear vibrating screen 1020-2

- Customization: Available

- Customized logo: Min. order 1 units

Introduction

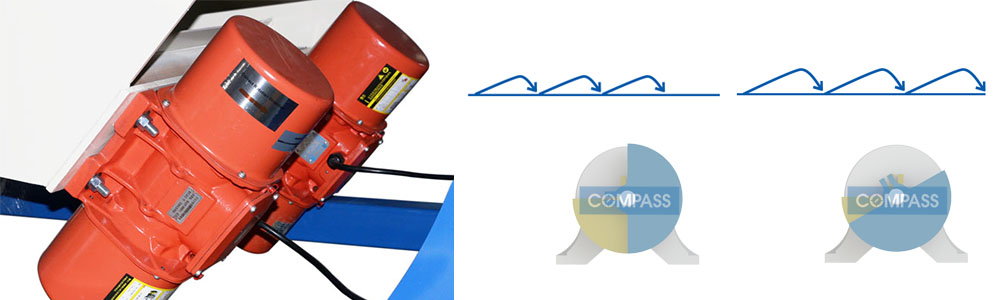

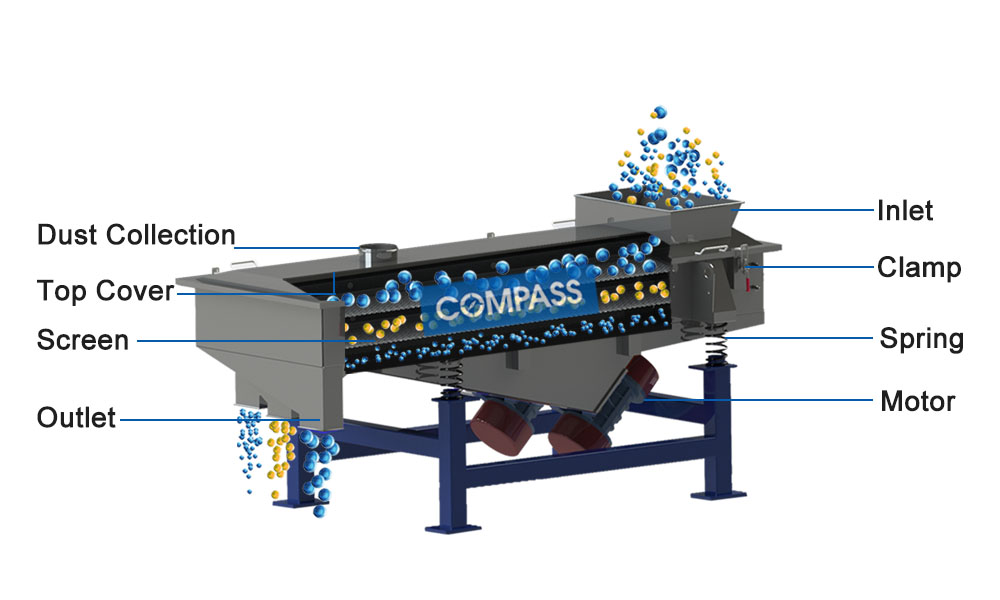

The horizontal vibration motor drives the linear sieve deck to move horizontally and radially. The products move along the linear trajectory from the inlet to the outlet. In this process, products smaller than the mesh enter the next deck and materials larger than the mesh enter the next layer, which be discharged through the discharge port.

The linear vibrating screen has the characteristics of simple structure, heavy duty and durable; screen size is 1 to 10 square meters, complete models, and wide applicability. It is very suitable for users who have customized needs for output and equipment size.

Features:

- High capacity, max 50 cubic meter/hour.

- One to five deck option.

- Mesh size 0.3mm ~ 20mm.

- Bouncing ball cleaning.

- Customized height and deck.

Technical Data

| Model NO. | Motor | Screen Decks | Screen size | Amplitude | Vibration Force | Vibration Frequency | Weight |

| Kw | ㎡ | MM | Kn | KG | |||

| Linear 0820-1 | 1.1 | 1 | 1.6 | 3~8 | 10000 | 960 | 650 |

| Linear 0820-2 | 1.1 | 2 | 1.6 | 3~8 | 10000 | 960 | 700 |

| Linear 0820-3 | 1.1 | 3 | 1.6 | 3~8 | 10000 | 960 | 750 |

| Linear 1020-1 | 1.1 | 1 | 2.0 | 3~8 | 16000 | 960 | 750 |

| Linear 1020-2 | 1.1 | 2 | 2.0 | 3~8 | 16000 | 960 | 870 |

| Linear 1020-3 | 1.1 | 3 | 2.0 | 3~8 | 16000 | 960 | 930 |

| Linear 1030-1 | 1.5 | 1 | 3.0 | 3~8 | 30000 | 960 | 800 |

| Linear 1030-2 | 1.5 | 2 | 3.0 | 3~8 | 30000 | 960 | 870 |

| Linear 1030-3 | 1.5 | 3 | 3.0 | 3~8 | 30000 | 960 | 940 |

| Linear 1030-4 | 1.5 | 4 | 3.0 | 3~8 | 30000 | 960 | 1010 |

| Linear 1030-5 | 1.5 | 5 | 3.0 | 3~8 | 30000 | 960 | 1080 |

| Linear 1530-1 | 3 | 1 | 4.5 | 3~8 | 40000 | 960 | 1700 |

| Linear 1530-2 | 3 | 2 | 4.5 | 3~8 | 40000 | 960 | 1800 |

| Linear 1530-3 | 3 | 3 | 4.5 | 3~8 | 40000 | 960 | 1900 |

| Linear 2040-1 | 4.7 | 1 | 8.0 | 3~8 | 60000 | 960 | 2980 |

| Linear 2040-2 | 4.7 | 2 | 8.0 | 3~8 | 60000 | 960 | 3100 |

| Linear 2040-3 | 4.7 | 3 | 8.0 | 3~8 | 60000 | 960 | 3200 |

| Linear 2050-1 | 5.8 | 1 | 10.0 | 3~8 | 60000 | 960 | 4700 |

| Linear 2050-2 | 5.8 | 2 | 10.0 | 3~8 | 60000 | 960 | 4800 |

| Linear 2050-3 | 5.8 | 3 | 10.0 | 3~8 | 60000 | 960 | 4900 |

Download

Dimension drawing download.

PDF catalog download.

User benefit:

Customization, fully match your production lines and products.

The linear vibration screen equipment’s inlet height, outlet height, inlet shape, outlet shape, screen length and width, etc. can all be custom designed and produced according to customer needs, perfectly connecting upstream and downstream equipment.

1. sieve machine dimension.

2. deck Types.

2. deck Types.

Linear screening equipment has a variety of optional screen structures and can be used to process a variety of products in the food, mineral, and chemical industries.

- Wire mesh deck with maximum opening ratio to handle mineral powders and granules.

- The rod deck has a smooth surface and will not damage the product. It is suitable for treating black water, earthworms and other insects.

- Punching plate (circular hole, square hole and other special-shaped holes), processing flake products, such as kelp, dried fish, important pills, etc.

- Polyurethane deck, processing solid-liquid mixture, cow dung, sand, etc.

High capacity.

The linear vibrating sifter has a maximum deck size of 2*5 meters, which allows its maximum feeding capacity to reach 50 cubic meters or 30 tons per hour.

Users can adjust the vibration amplitude by adjusting the angle of the counterweights at both ends of the motor to obtain the best separating efficiency performance.