Table of Contents

How Frac Sand Gyratory Screening Technology is Revolutionizing the Oil and Gas Industry

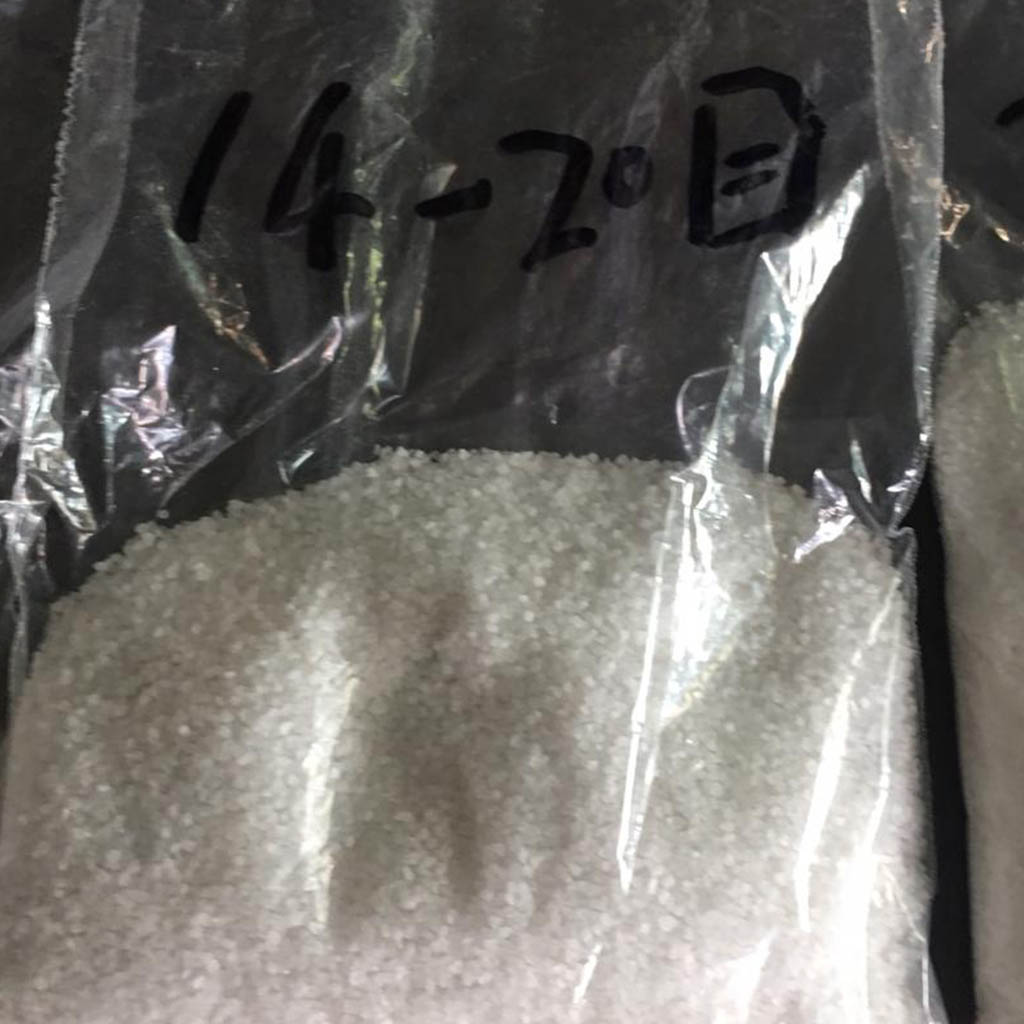

The oil and gas industry is undergoing a revolution, and it’s all thanks to the introduction of frac sand gyratory screening technology. This innovative technology is revolutionizing the way oil and gas companies extract and process resources, making the process more efficient and cost-effective.| Model NO. | Material | Moist | Mesh size | Capacity Tons /Hour |

| G2036-3 | Silica sand, quartz sand, frac sand | Dry | 40 / 70 / 140 | 6 |

| 2G2036-3 | Silica sand, quartz sand, frac sand | Dry | 40 / 70 / 140 | 10 |

| 4G2036-2 | Silica sand, quartz sand, frac sand | Dry | 70 / 140 | 15 |

The introduction of frac sand gyratory screening technology has had a huge impact on the oil and gas industry. This technology has allowed companies to extract and process resources more quickly and efficiently, resulting in cost savings and increased productivity. Additionally, this technology has improved the safety of the process, as it eliminates the need for manual sorting and reduces the risk of human error.

Overall, frac sand gyratory screening technology is revolutionizing the oil and gas industry. This innovative technology is making the extraction and processing of resources more efficient and cost-effective, while also improving safety. As this technology continues to evolve, it will no doubt continue to revolutionize the industry for years to come.

The introduction of frac sand gyratory screening technology has had a huge impact on the oil and gas industry. This technology has allowed companies to extract and process resources more quickly and efficiently, resulting in cost savings and increased productivity. Additionally, this technology has improved the safety of the process, as it eliminates the need for manual sorting and reduces the risk of human error.

Overall, frac sand gyratory screening technology is revolutionizing the oil and gas industry. This innovative technology is making the extraction and processing of resources more efficient and cost-effective, while also improving safety. As this technology continues to evolve, it will no doubt continue to revolutionize the industry for years to come.