Table of Contents

How Vibration Sieve Machines Improve Silica Sand Quality

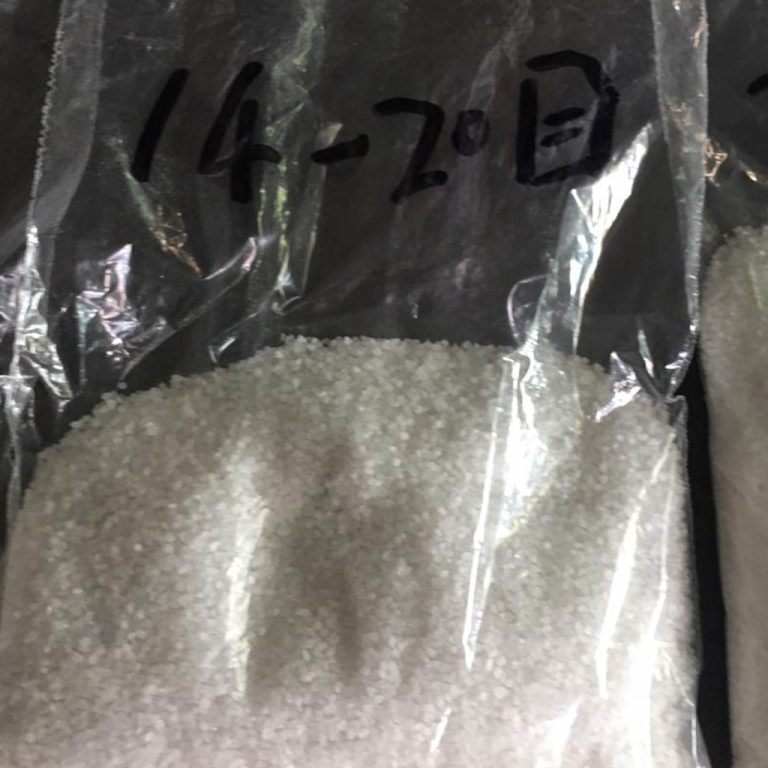

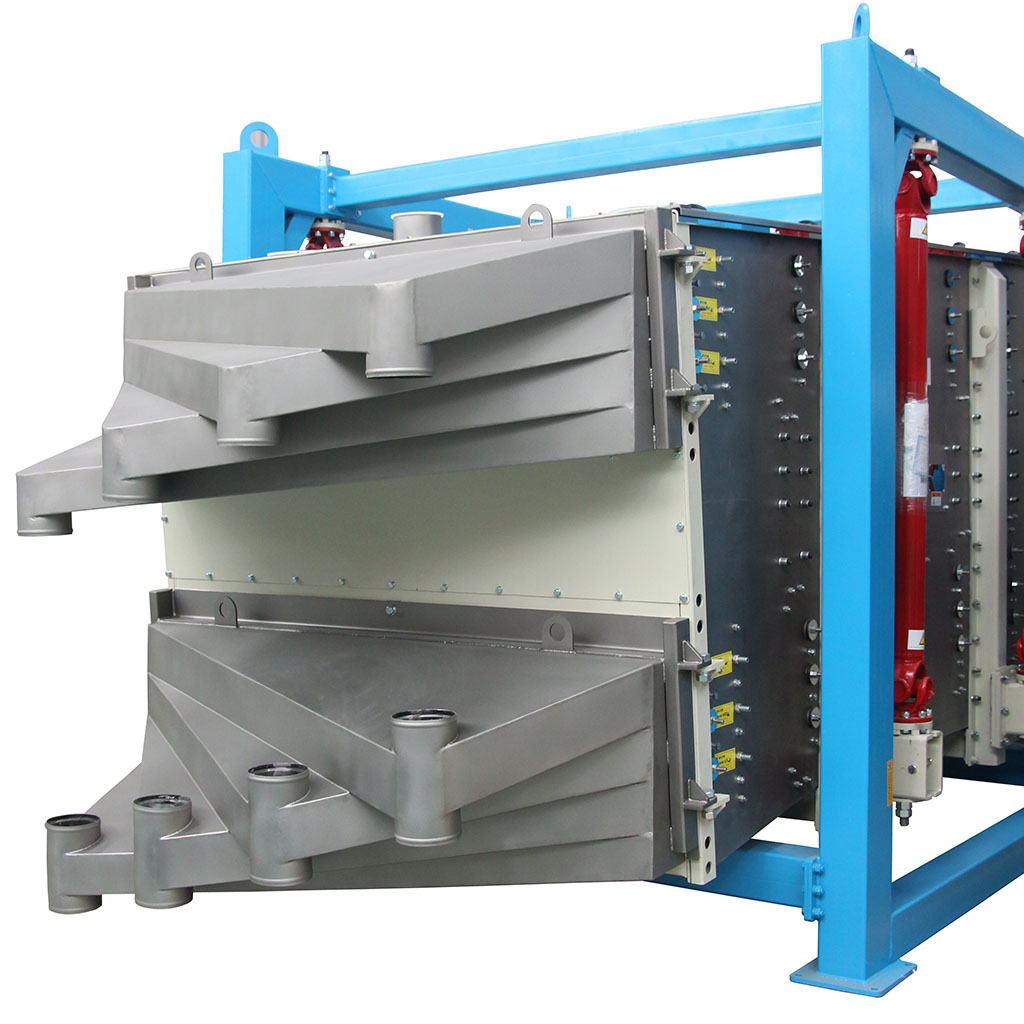

Vibration sieve machines are an effective way to improve the quality of silica sand. The machines use vibration to separate the sand into different grades, allowing for a more consistent product. The process begins with the sand being fed into the machine. The vibration causes the sand to move around, allowing the heavier particles to settle at the bottom and the lighter particles to rise to the top. The heavier particles are then removed, leaving behind the finer, more consistent sand.| Model NO. | Material | Moist | Mesh size | Capacity Tons /Hour |

| G2036-5 | Silica sand, quartz sand, frac sand | Dry | 10 / 30 /40 / 70 / 140 | 5 |

| 2G2036-5 | Silica sand, quartz sand, frac sand | Dry | 5 / 20 / 40 / 70 / 140 | 9 |

| 4G2036-2 | Silica sand, quartz sand, frac sand | Dry | 40 / 70 | 17 |

The Benefits of Using Vibration Sieve Machines for Silica Sand Processing

Silica sand processing is an important part of many industrial processes, and the use of a vibration sieve machine can help to ensure that the process is efficient and effective. Vibration sieve machines are used to separate particles of different sizes, and they are especially useful for separating silica sand into different grades. Here are some of the benefits of using a vibration sieve machine for silica sand processing: 1. Increased Efficiency: Vibration sieve machines are designed to quickly and accurately separate particles of different sizes. This means that the process of separating silica sand into different grades can be completed much faster than with manual methods. This increased efficiency can help to reduce costs and improve productivity. 2. Improved Quality: Vibration sieve machines are designed to be highly accurate, which means that the quality of the silica sand produced is much higher than with manual methods. This improved quality can help to ensure that the silica sand is suitable for its intended use. 3. Reduced Waste: Vibration sieve machines are designed to be highly efficient, which means that less material is wasted during the process. This can help to reduce costs and improve the overall efficiency of the process.

Overall, the use of a vibration sieve machine for silica sand processing can provide a number of benefits. It can help to increase efficiency, improve quality, and reduce waste, all of which can help to improve the overall process.

3. Reduced Waste: Vibration sieve machines are designed to be highly efficient, which means that less material is wasted during the process. This can help to reduce costs and improve the overall efficiency of the process.

Overall, the use of a vibration sieve machine for silica sand processing can provide a number of benefits. It can help to increase efficiency, improve quality, and reduce waste, all of which can help to improve the overall process.