Table of Contents

How Gyratory Screen Equipment Improves Frac Sand Quality

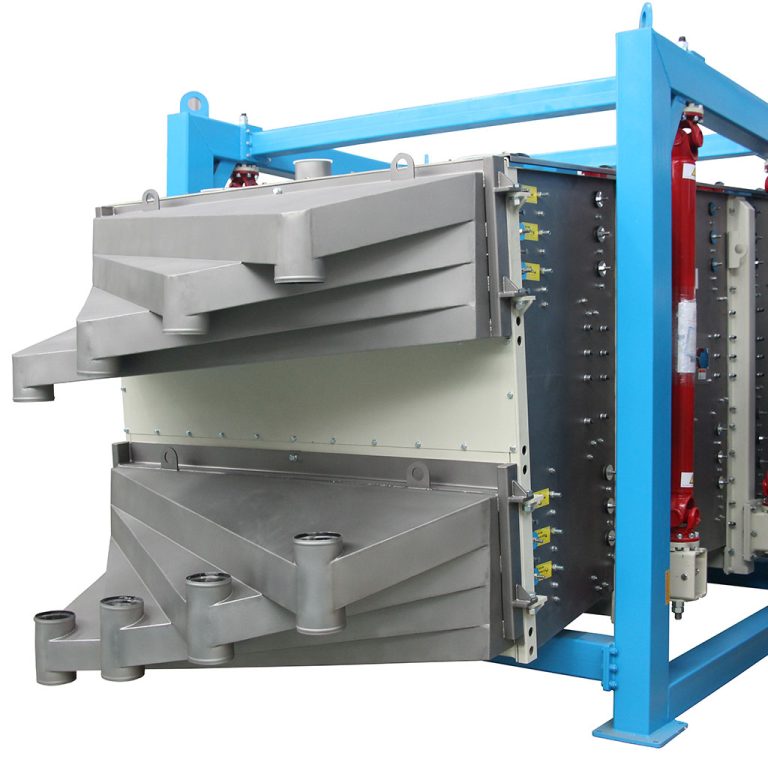

Gyratory screen equipment is an essential tool for improving the quality of frac sand. This type of equipment uses a unique gyratory motion to separate particles of different sizes, shapes, and densities. The gyratory motion creates a vortex that allows the particles to be separated based on their size, shape, and density. This process is highly efficient and can be used to separate particles down to as small as 20 microns. The gyratory motion of the equipment also helps to reduce the amount of dust and fines that are created during the screening process. This is because the gyratory motion creates a centrifugal force that helps to keep the particles in the center of the screen, reducing the amount of dust and fines that are created. The gyratory motion also helps to reduce the amount of time it takes to screen the frac sand. This is because the gyratory motion helps to keep the particles in the center of the screen, allowing them to be screened more quickly. Finally, the gyratory motion helps to reduce the amount of energy that is required to screen the frac sand. This is because the gyratory motion helps to reduce the amount of friction between the particles and the screen, reducing the amount of energy that is required to move the particles. Overall, gyratory screen equipment is an essential tool for improving the quality of frac sand. This type of equipment uses a unique gyratory motion to separate particles of different sizes, shapes, and densities. The gyratory motion also helps to reduce the amount of dust and fines that are created during the screening process, reduce the amount of time it takes to screen the frac sand, and reduce the amount of energy that is required to screen the frac sand.The Benefits of Investing in Gyratory Screen Equipment for Frac Sand Production

Gyratory screen equipment is an essential component of frac sand production. This type of equipment is used to separate and classify particles of different sizes, allowing for the production of high-quality frac sand. Investing in gyratory screen equipment can provide numerous benefits to frac sand producers. First, gyratory screen equipment is highly efficient. It can quickly and accurately separate particles of different sizes, allowing for the production of high-quality frac sand. This type of equipment is also designed to be low-maintenance, reducing the need for frequent repairs and downtime. Second, gyratory screen equipment is cost-effective. It is designed to be energy-efficient, reducing the cost of energy consumption. Additionally, gyratory screen equipment is designed to be durable, meaning it can last for many years with minimal maintenance. This reduces the need for frequent replacements, saving money in the long run. Third, gyratory screen equipment is safe. It is designed to be user-friendly, reducing the risk of accidents and injuries. Additionally, gyratory screen equipment is designed to be dust-free, reducing the risk of respiratory illnesses.| Model NO. | Material | Moist | Mesh size | Capacity Tons /Hour |

| G2036-5 | Silica sand, quartz sand, frac sand | Dry | 10 / 30 /40 / 70 / 140 | 5 |

| 2G2036-5 | Silica sand, quartz sand, frac sand | Dry | 5 / 20 / 40 / 70 / 140 | 9 |

| 4G2036-2 | Silica sand, quartz sand, frac sand | Dry | 40 / 70 | 17 |

Finally, gyratory screen equipment is reliable. It is designed to be reliable and consistent, ensuring that frac sand producers can produce high-quality frac sand on a consistent basis.

Finally, gyratory screen equipment is reliable. It is designed to be reliable and consistent, ensuring that frac sand producers can produce high-quality frac sand on a consistent basis.