Table of Contents

Exploring the Benefits of Bentonite in Industrial Screening Applications

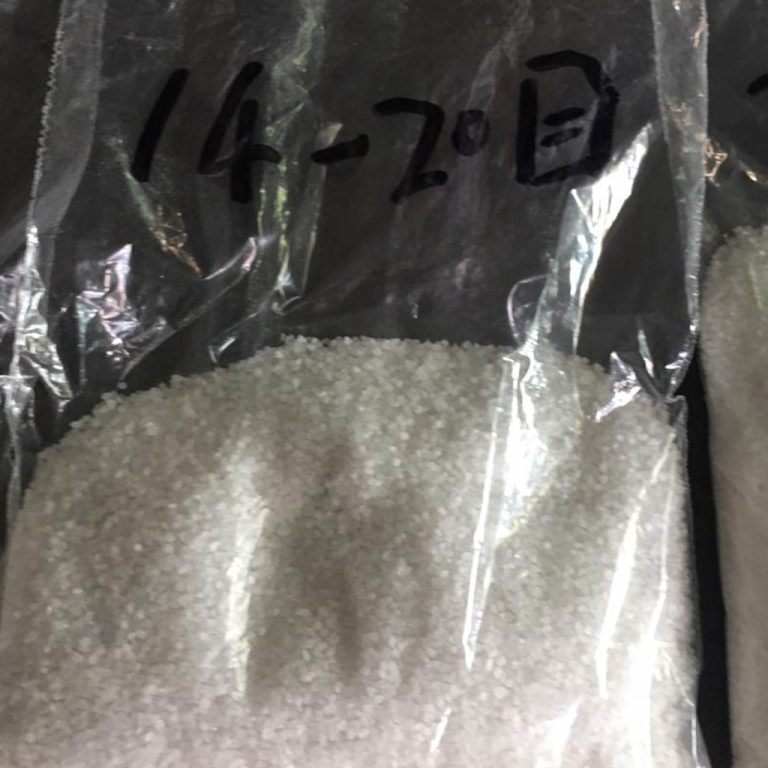

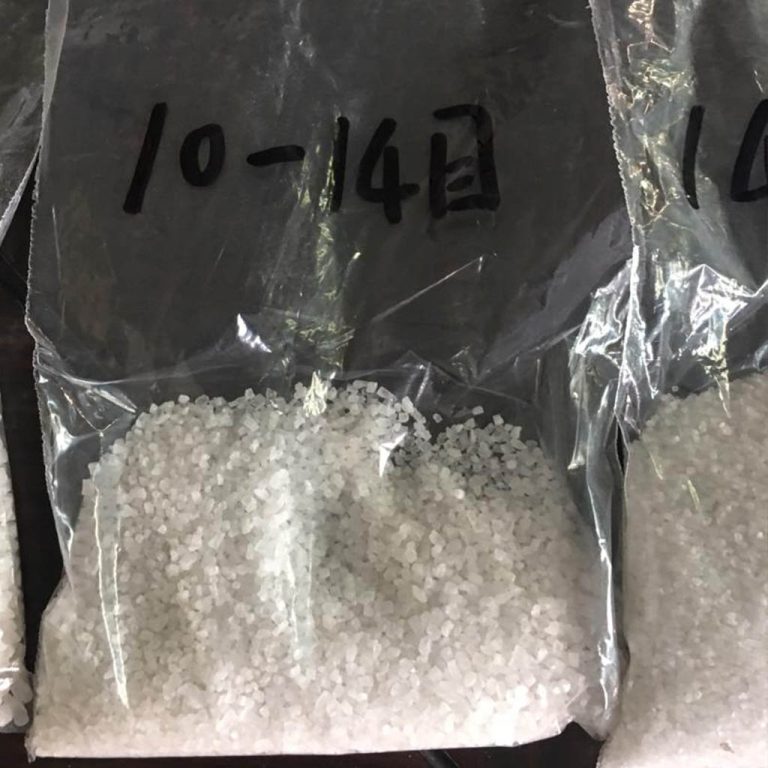

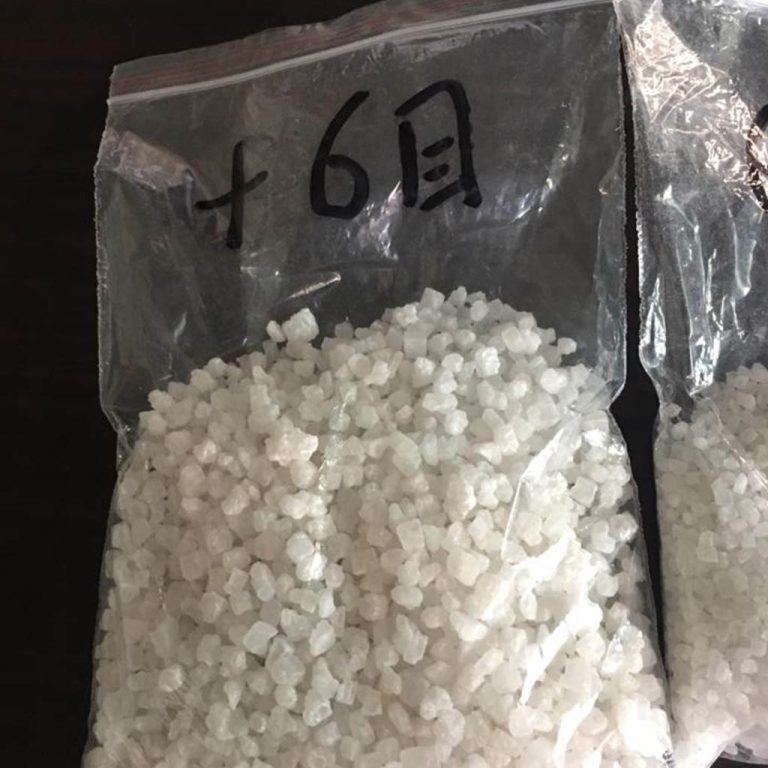

Bentonite is a type of clay that has been used for centuries in industrial applications. It has a wide range of uses, from industrial filtration to agricultural applications. In recent years, bentonite has become increasingly popular for use in industrial screening applications. This is due to its unique properties, which make it an ideal material for this purpose. Bentonite is a naturally occurring clay that is composed of montmorillonite, a type of clay mineral. It is highly absorbent and has a high cation exchange capacity, which makes it ideal for use in industrial screening applications. The absorbent nature of bentonite allows it to trap and hold particles, making it an effective filter for a variety of materials. Bentonite is also highly resistant to chemical attack, making it an ideal material for use in industrial screening applications. This is because it can withstand harsh chemicals and temperatures without breaking down or becoming damaged. This makes it an ideal material for use in industrial processes that involve the use of harsh chemicals or high temperatures. Bentonite is also highly resistant to abrasion, making it an ideal material for use in industrial screening applications. This is because it can withstand the wear and tear of industrial processes without becoming damaged or breaking down. This makes it an ideal material for use in industrial processes that involve the use of abrasive materials.| Mesh size mm | Mesh numbe/ in2 | Wire Dia mm | Open Area % |

| 0.212 | 70 | 0.125 | 40 |

| 0.18 | 80 | 0.125 | 35 |

| 0.16 | 90 | 0.1 | 35 |

| 0.15 | 100 | 0.1 | 36 |

| 0.14 | 110 | 0.09 | 37 |

| 0.125 | 120 | 0.09 | 34 |

How Bentonite Can Improve Efficiency and Productivity in Industrial Screening Processes

Bentonite is a type of clay that has been used for centuries in industrial processes. It has a wide range of applications, including use in industrial screening processes. Bentonite can be used to improve efficiency and productivity in industrial screening processes by providing a number of benefits. First, bentonite can help to reduce the amount of time needed to complete the screening process. Bentonite is highly absorbent, which means it can quickly absorb moisture and other particles from the material being screened. This helps to reduce the amount of time needed to complete the screening process, as the material is already partially screened before it even enters the screening machine.

Second, bentonite can help to reduce the amount of material that needs to be screened. Bentonite is highly effective at trapping particles, which means that it can help to reduce the amount of material that needs to be screened. This can help to reduce the amount of time needed to complete the screening process, as well as reduce the amount of material that needs to be disposed of.

Third, bentonite can help to improve the accuracy of the screening process. Bentonite is highly effective at trapping particles, which means that it can help to ensure that only the desired particles are screened. This can help to improve the accuracy of the screening process, as well as reduce the amount of material that needs to be disposed of.

Finally, bentonite can help to reduce the amount of energy needed to complete the screening process. Bentonite is highly absorbent, which means that it can help to reduce the amount of energy needed to complete the screening process. This can help to reduce the amount of energy needed to complete the screening process, as well as reduce the amount of energy needed to dispose of the material.

Overall, bentonite can be used to improve efficiency and productivity in industrial screening processes. It can help to reduce the amount of time needed to complete the screening process, reduce the amount of material that needs to be screened, improve the accuracy of the screening process, and reduce the amount of energy needed to complete the screening process.

First, bentonite can help to reduce the amount of time needed to complete the screening process. Bentonite is highly absorbent, which means it can quickly absorb moisture and other particles from the material being screened. This helps to reduce the amount of time needed to complete the screening process, as the material is already partially screened before it even enters the screening machine.

Second, bentonite can help to reduce the amount of material that needs to be screened. Bentonite is highly effective at trapping particles, which means that it can help to reduce the amount of material that needs to be screened. This can help to reduce the amount of time needed to complete the screening process, as well as reduce the amount of material that needs to be disposed of.

Third, bentonite can help to improve the accuracy of the screening process. Bentonite is highly effective at trapping particles, which means that it can help to ensure that only the desired particles are screened. This can help to improve the accuracy of the screening process, as well as reduce the amount of material that needs to be disposed of.

Finally, bentonite can help to reduce the amount of energy needed to complete the screening process. Bentonite is highly absorbent, which means that it can help to reduce the amount of energy needed to complete the screening process. This can help to reduce the amount of energy needed to complete the screening process, as well as reduce the amount of energy needed to dispose of the material.

Overall, bentonite can be used to improve efficiency and productivity in industrial screening processes. It can help to reduce the amount of time needed to complete the screening process, reduce the amount of material that needs to be screened, improve the accuracy of the screening process, and reduce the amount of energy needed to complete the screening process.